PUBLIC ART:

ALUMINUM & STAINLESS FRAME WITH BLUE-FRIT GLASS;

CARVED, KILN-FIRED, TEMPERED, LAMINATED & BACK-LIT

THE PROJECT:

ARTIST / CLIENT: – Marianne Nicolson (‘Tayagila’ogwa)

TITLE: – “Rise And Fall” (Link to video)

Dzawada’enuxw artist, Marianne Nicolson required a way of ‘cladding’ 4 concrete columns in Burnaby BC, using glass as the primary medium.

As the project developed, we tested several designs for this installation before settling on the one articled here.

THE DESIGN:

With any art glass project, two considerations are of equal importance:

- The ‘type’ of glass and how it will relate to its surroundings, in situ.

- How light – both natural and generated – will affect the reading of the work.

In this case we had multi-faceted glass sculptures, located outdoors, affected by shifting natural light, and viewed from many different angles.

The work was also located in front of a three story glass atrium. Ideally, the finish of our glass would stand apart from, yet still reference, the materiality of this façade.

For several years I’ve been developing ways to utilize frit-coated float glass and ’embed’ clear artwork into it. This project presented a great opportunity to do just that by using a matte-coloured panel with clear carved art line.

We would further highlight the sculpted art lines by using a dedicated light system.

The look of our material would now ‘de-couple’ itself from that of the building façade.

THE BUILD:

Experimenting began with LED edge-lighting through Low Iron glass, but the light wouldn’t travel far enough through the material with the blue colour-coating applied. Other colour-coatings proved equally problematic for edge-lighting…

Next up were exterior spot light tests. Unfortunately, the glass would look fine from one angle, but then show a lighting glare from a different perspective. So, that wasn’t going to work, either.

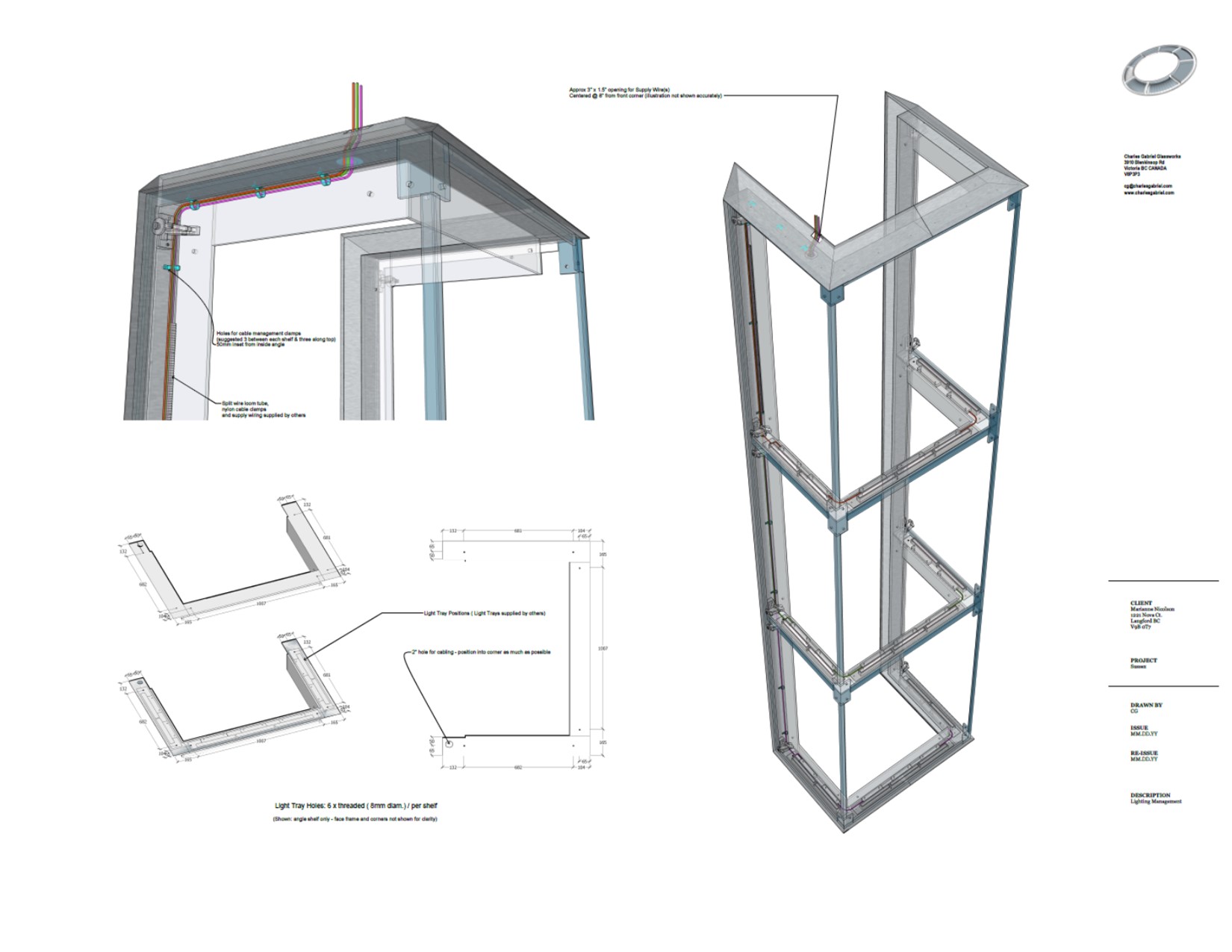

Ultimately, it made the best sense to stand the glass away from the columns and back-light it. This would require larger panels on a robust support system with a bespoke lighting solution.

In addition to holding 1300kg of material, each support frame needed to provide access to the lighting fixtures, and by design, not interrupt the visual flow of the artwork.

I revised the frame design several times – constantly minimizing the appearance of the support system, until it provided almost edge to edge light coverage through the art lines in the glass.

Each 21′ high set of 9 glass carvings would be framed with a stainless steel trim.

FIRST THINGS:

Townline (site developer) surveyed their finished columns and provided precise dimensions. This allowed me to accurately size my designs of the monolithic frames, and glass panels.

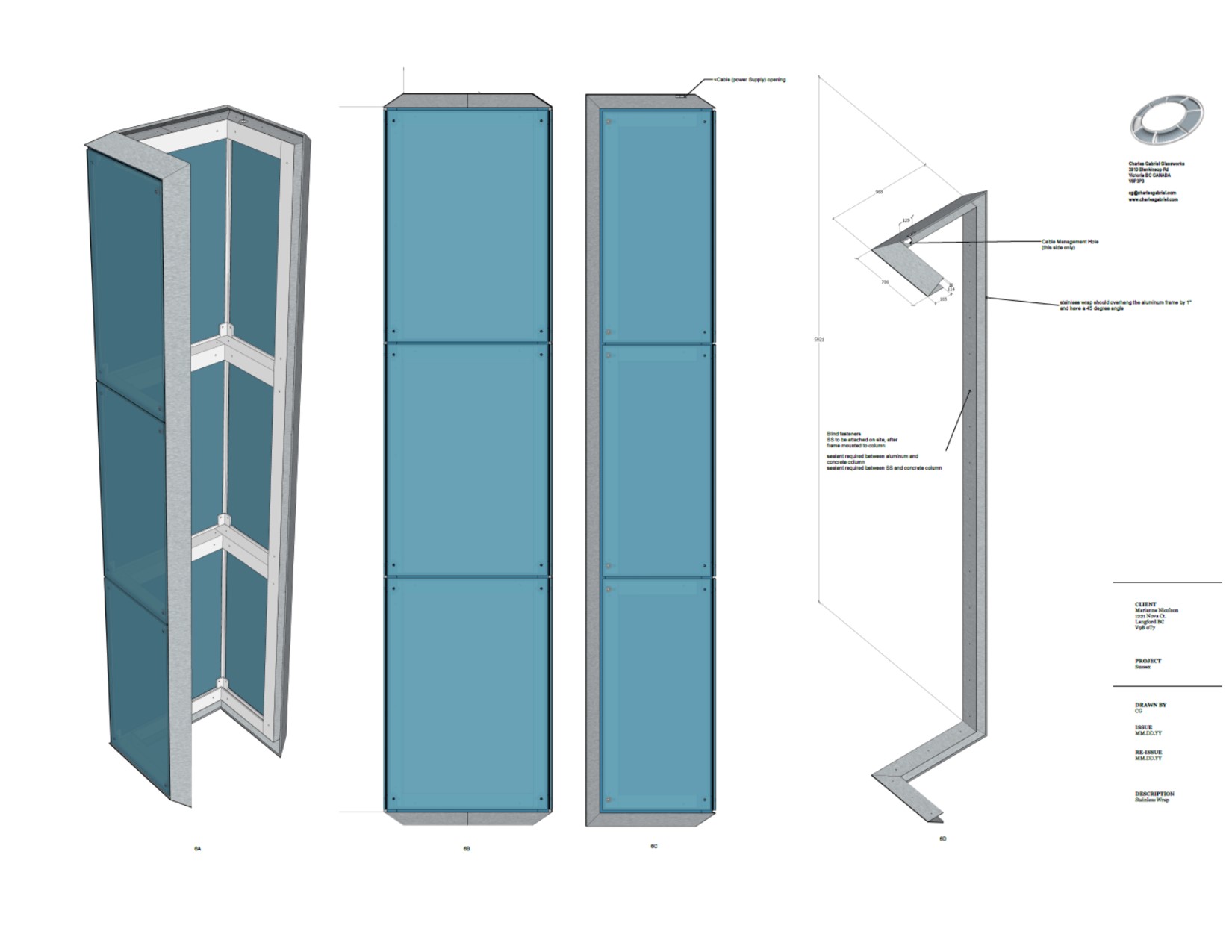

… some page excerpts from the model/layout – so you can build one at home…😜

With model dimensions finalized, physical production could begin.

METAL:

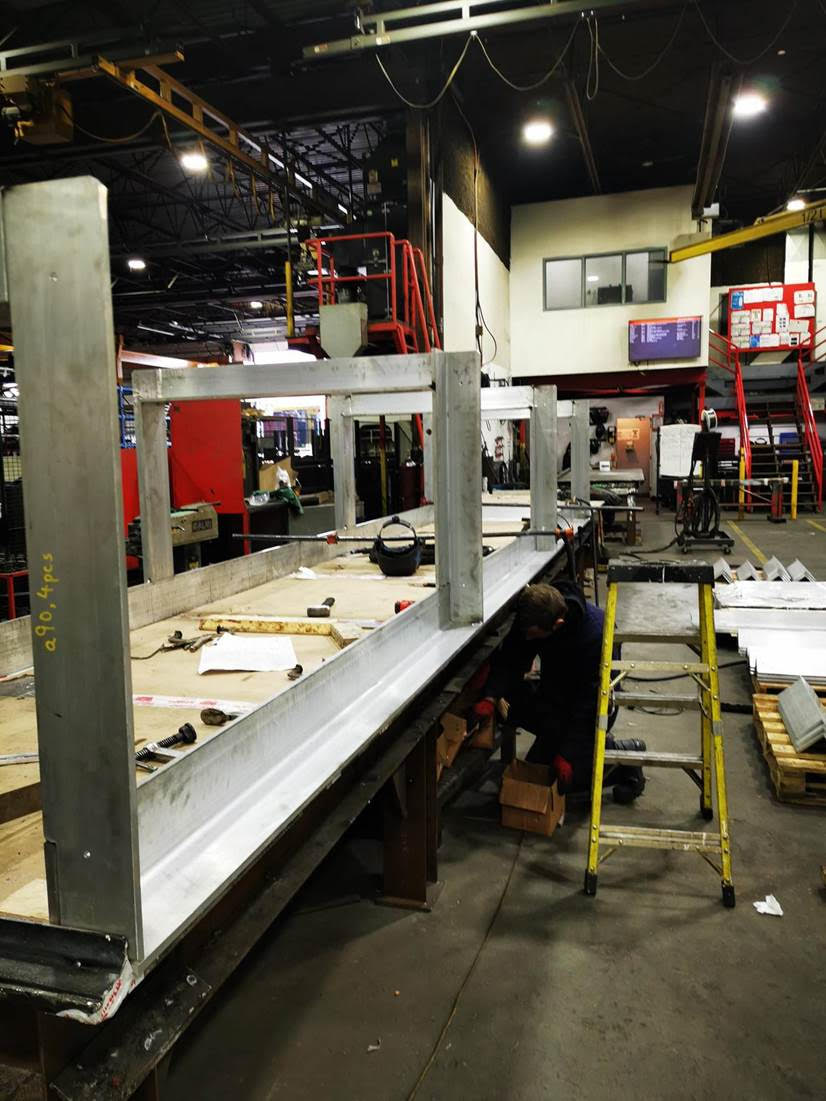

Metal fabrication and on site frame installation was handled by Marcon MetalFab.

Marcon has the gear and workforce required to fabricate just about anything imaginable, so we were very excited that they were taking on our bespoke project.

STARTING THE GLASS:

Glass cutting, frit application, post-carve tempering, and ultimately lamination – was all handled by the great team at Garibaldi Glass Industries -Vancouver BC.

We have partnered with Garibaldi on many complex projects and could not imagine a more capable manufacturer.

Besides the processing done by Garibaldi Glass Industries, every single panel required two more specialized kiln firings.

All this additional kiln work was superbly executed by Gilchrist Glass Bending.

A suction cup/hoist system is used to carefully position the glass panel into the kiln.

The carving would be face up in the kiln, so the artist needed to allow spaces for these suction cups between the design lines.

The template example below shows how we positioned the cups between carved lines.

Glass carving gets underway…

HARDWARE:

I blasted the custom stainless standoff caps and prepped them for powder-coating.

Victoria Powder Coating provided a great colour match to our glass frit.

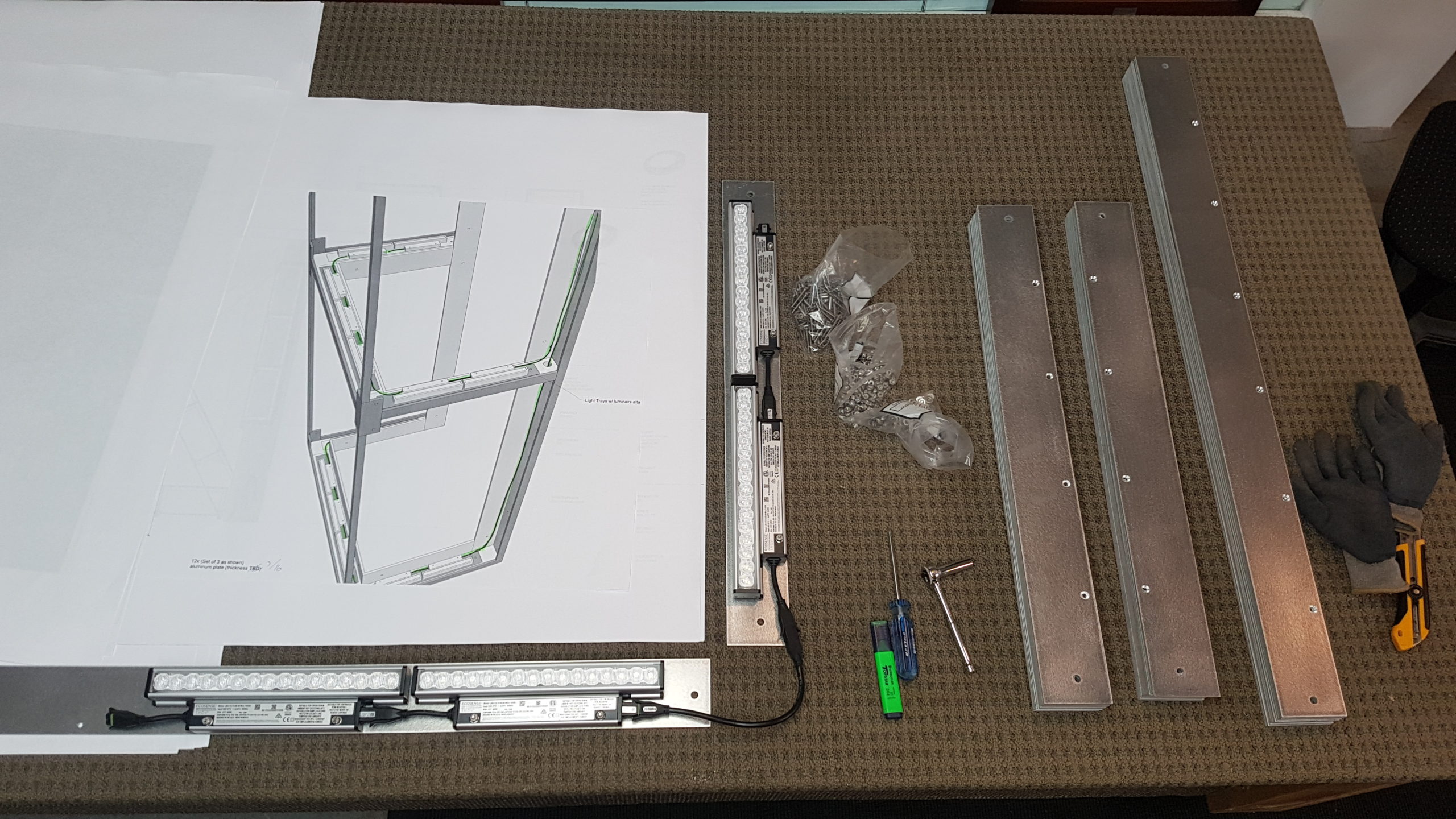

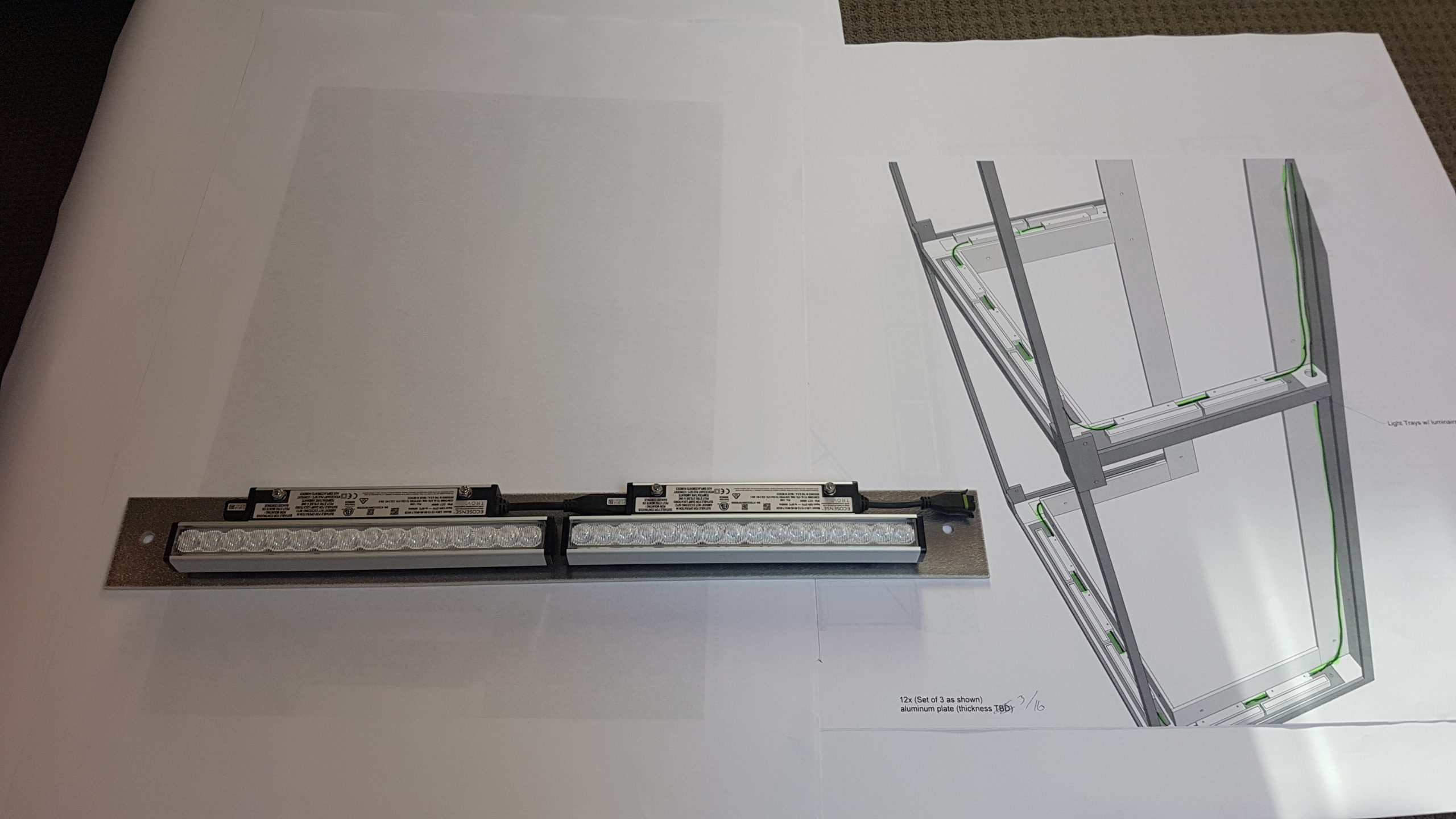

I built a full scale mock up to help work out the luminaire settings.

I had Victoria Waterjet cut aluminum trays for the luminaires. By incorporating a set screw into one edge these boards , we could adjust the light wash angle of the whole board.

Gaia Photonics was instrumental in providing the bespoke lighting we could fit into this project.

Hinges sourced from Manfred Frank – New Zealand – would allow the side panels to open for maintenance access.

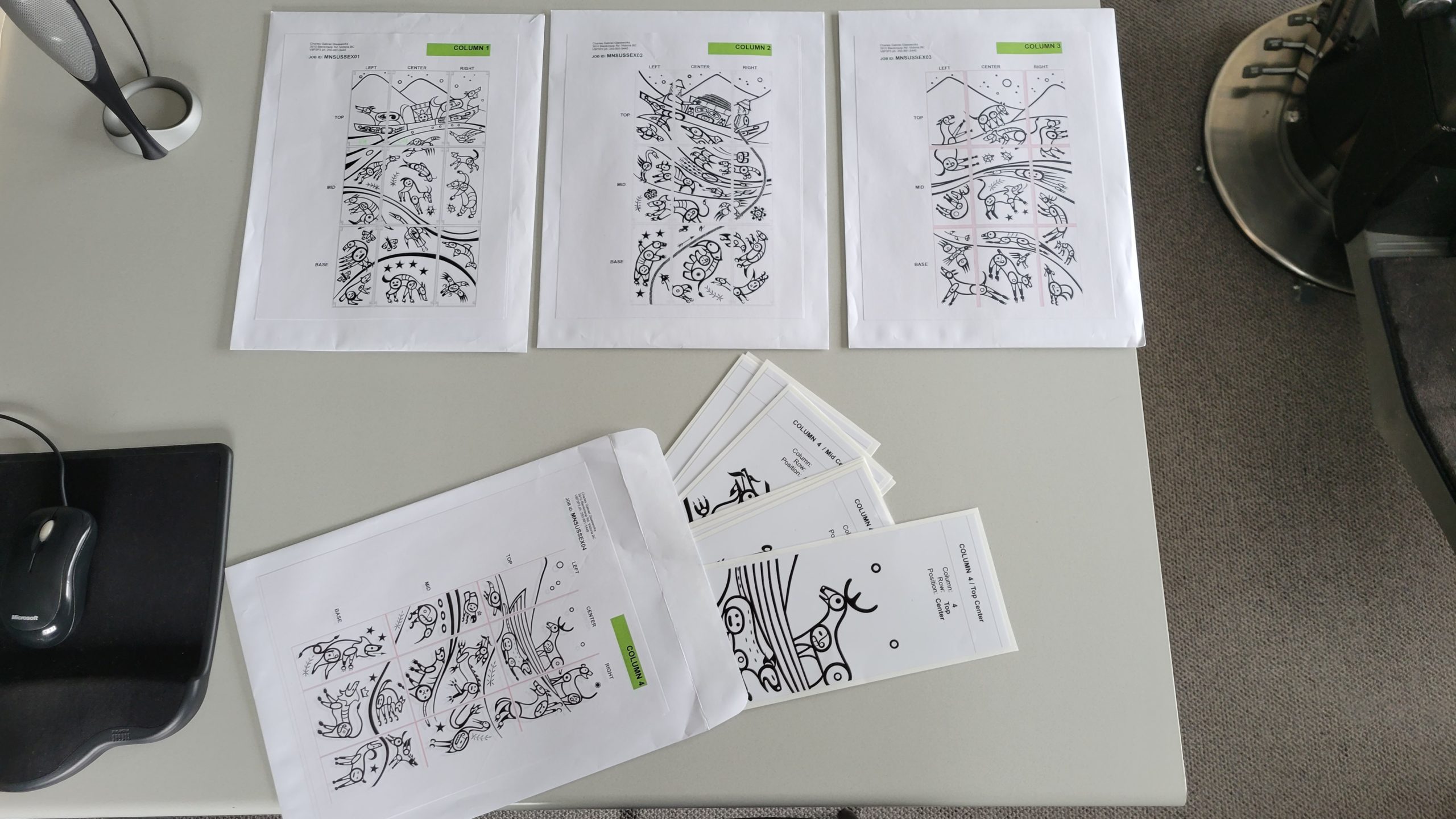

Vector line-work, printing and plotting – courtesy of Garside Displays – Victoria BC

INSTALLATION:

Throughout the carving, multiple kiln-firings, tempering and lamination, the glass moved between several facilities.

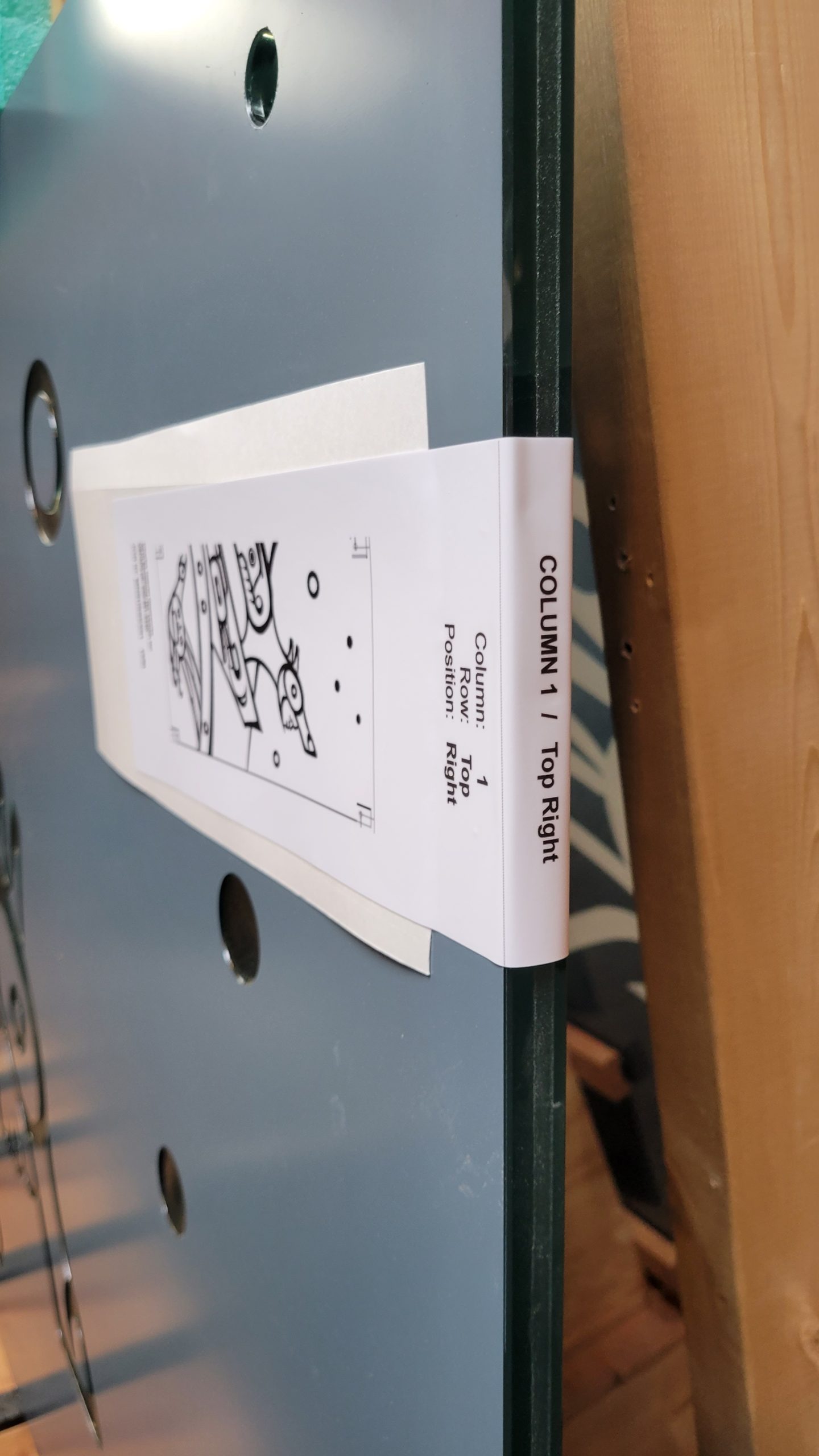

To keep everything organized, I used the original artwork to design “re-useable” labels that stayed with each panel throughout production.

Designed to wrap over the ends, the label ID could also be read while the panels were stacked on racks. This made on-site ID and sorting a lot easier.

Marcon Metalfab installed the frames, ready for glass.

Its a long reach with some panels weighing close to 300lbs. Props to Optimum Studios for rising to the challenge.

The Optimum team carefully handled all the glazing and lighting installation.

Lighting required final onsite tweaking by Gaia Photonics once panels were in situ.

THE RESULT:

Like so many projects undertaken during 2020-21, we weren’t immune to the new challenges – primarily, sudden material supply shortages. We learned to adjust on the fly with some supplies and manufacturing – at times, midway through the lengthy design/build. We were fortunate to have the option to do so. Occasionally, supply issues led to scheduling conflicts, but thanks to the enthusiasm, skill, and adaptability of all involved, we managed to successfully produce and install this unique work of fine art on budget and on schedule (-ish).

With a mask on.

The general consensus, I believe, is that the final result has exceeded expectations.

Massive kudos to everyone involved!

PROJECT MATERIALS CONCEPT / FRAME DESIGN / MODELLING AND RENDERS / SUPPLY SOURCING / BUILD COORDINATION / GLASS CARVING / CAT-WRANGLING, ETC:

*

ARTIST / CLIENT: – Marianne Nicolson

ARTWORK TITLE: – “Rise And Fall” (Link to video)

LOCATION: – 6050 Sussex Ave, Burnaby BC CANADA

*

ACCOMPLICES:

Gilchrist Glass Bending – 3100 Wilkinson Rd RR 2, Mill Bay, BC V0R 2P2

Garibaldi Glass Industries – 8183 Wiggins St, Burnaby BC V3N 0C4

Marcon MetalFab – 7156 Brown St, Delta British Columbia V4G 1G8

Garside Displays – 60 Crease Avenue, Victoria, British Columbia V8Z 1S3

Gaia Photonics – #7-2064 Henry Avenue West, Sidney, BC V8L 5Y1

Manfred Frank – 66 Cryers RoadEast Tamaki 2013Auckland NZ

Optimum Glass Studios – 202 – 8475 Ontario St, Vancouver BC V5X 3E8

Victoria Waterjet – 869 Van Isle Way, Victoria BC V9B 5R8

RJC Engineers – 645 Tyee Road Suite 220, Victoria BC V9A 6X5

Be First to Comment