Completed upper sections of screen installed

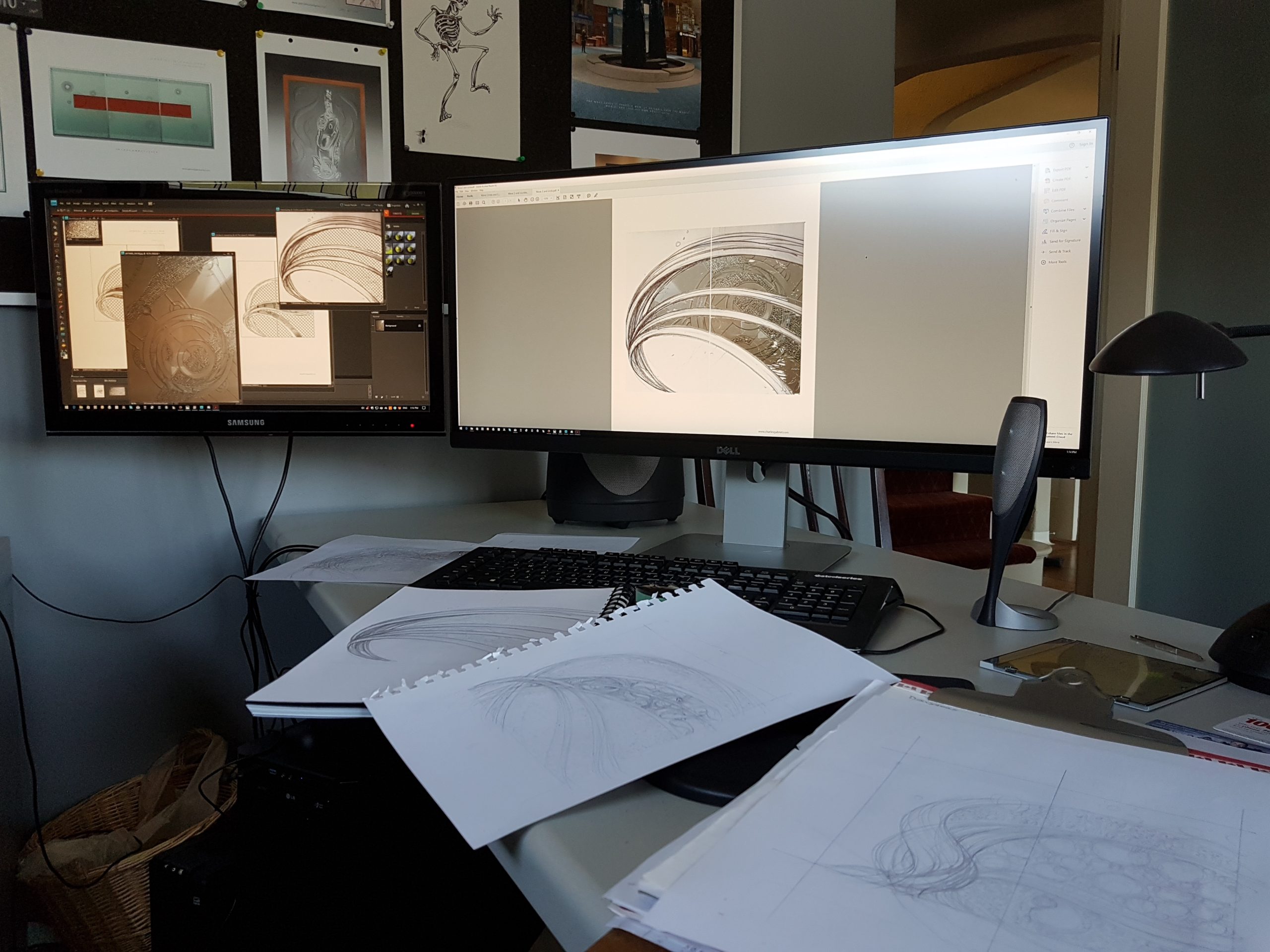

some prelim design ideas

Pencil sketch

vector drawings enlarged and printed on vinyl resist

Raw sandblast complete

carved, kiln-fired, tempered & laminated panels are installed

lower section of glasses

For this project, the clients wanted a privacy screen with some clear areas for visibility, and the frameless panels needed to meet engineering standards for the strong winds off the ocean. We designed a solution that utilized a kiln-fired carved design laminated to multiple layers of SGP clear intermediate that created a clear view through the field areas of the glass. Firstly, to reference the Pacific Coast water view, I created a ‘fluid’ style of line art interweaving like reeds, water, kelp, or wind might (initially with a pencil, and then on the computer so that I could enlarge the vector graphics to full panel size. Critical in the event of a breakage, the complicated pattern could be replicated and line up with the others). The design also needed to have several clear spots within the pattern to affix the suctions cups that we needed to lift the large heavy panels into the kiln. Secondly, the art-glass needed to be no more than 10mm thick, carved and tempered because by the time it was laminated to the structural base glass, the panel weight even at that thickness was already going to be very difficult to install.

This particular part of the gig was left to Dan and his crew from Clearlite Glass in Victoria. They designed ramps, rigging and a dolly system to roll the 4 x 600lb+ laminated panels down the narrow bank beside the building, and then erected a dedicated hoist system on site to tilt them up vertically, and lift into situ. Hats off to their knowhow and ingenuity!

Be First to Comment